TOA's Legacy of Manufacturing

Technological roots of Toa Industry can be

traced back to the two wheel motorcycle manufacturer, Marusho Motor Co.,

Ltd., which was second in starting the manufacture of motorcycles in

postwar Hamamatsu city.

Through creative manufacturing of Marusho Motors as represented by its iconic "Lilac" mtoorcycle, our founder, Yoshio Ukei, learned the "technology and the spirit of challenge".

And in the postwar Hamamatsu where numerous manufacturers large and small were starting their manufacturing, Ukei too founded Toa Industry dreaming of one day becoming an own brand manufacture company.

Hamamatsu people are known for their Yaramaika (Let's Do It) spirit. Yoshio Ukei too was a man of creativity and challenge, who would say "let's do it anyway".

The dumpling making machines of Toa Industry has not only replicated the speciality taste of customers' dumplings, but also inherited that spirit of "Yaramaika" that has supported the manufacturing of Japan.

Through creative manufacturing of Marusho Motors as represented by its iconic "Lilac" mtoorcycle, our founder, Yoshio Ukei, learned the "technology and the spirit of challenge".

And in the postwar Hamamatsu where numerous manufacturers large and small were starting their manufacturing, Ukei too founded Toa Industry dreaming of one day becoming an own brand manufacture company.

Hamamatsu people are known for their Yaramaika (Let's Do It) spirit. Yoshio Ukei too was a man of creativity and challenge, who would say "let's do it anyway".

The dumpling making machines of Toa Industry has not only replicated the speciality taste of customers' dumplings, but also inherited that spirit of "Yaramaika" that has supported the manufacturing of Japan.

1950s

Yoshio Ukei, the founder

Joined Marusho Motor Co., Ltd.

Yoshio Ukei, the founder of Toa

Industry. Immediately after graduating from high school, he joined

Marusho Motor Co., Ltd. Mr. Ito, the coroporate president of Marusho

Motor was a junior of Mr. Soichiro Honda and was active in "Art Shokai

Co., Ltd." and "Tokai Seiki Co., Ltd." as well. Ukei inherited their

spirit of manufacturing.

In 1951, our founder, Yoshio Ukei joined

Marusho Motor Co., Ltd. They were a motorbike manufacturer that

manufactured the famous "lilac" which is known for its innovative

designs such as the usage of shaft drive. Ukei worked for and

experienced various departments ranging from design to construction,

purchase to planning. The process of "manufacturing from zero" that he

learned at this time became the roots of originality of Toa Industry

which is continuing to this day.

1960s

From a subcontract factory

To become a manufacturer.

On August 1, 1963, Ukei founded "Toa Industry"

based on the experience accumulated in Marusho Motor. It was a start

with just 6 people. As a subcontractor of an automobile company, they

produced molds for car parts, and the business grew steadily, riding on

the wave of high economic growth and motorization. In 1966, he

incorporated Toa Industry Co., Ltd. Although there was an option to

expand the scale as an automobile parts manufacturing company, Ukei

could not forego the dream of becoming, not a sub-contractor, but a

"manufacturer of his own product", and so he continued to invest in

equipments and research of his original product.

One

of the traces of Toa Industry's efforts at becoming a vehicle

manufacturer is this pleasure boat. Unfortunately, it did not reach the

retail stage, but there is an advert with the name "water jet", showing

that it was at its final stage of release.

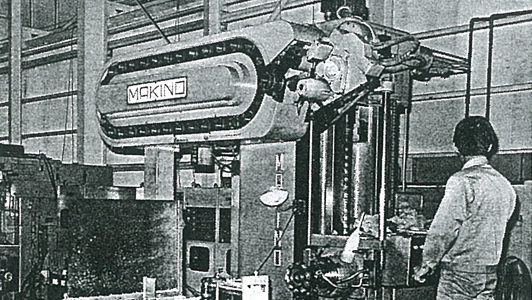

NC

milling machine that was introduced in 1964. For Toa Industry then,

this was an investment beyond its means, and some were worried of it

endangering the company management. However, this machine whose use was

unsure in the beginning, was in a few years time running in full

operation.

1970s

The research and development

of automated gyoza making machine begin.

Although it was natural for Ukei and Toa Industry

to find a way to success with motor vehicle development given his

experiences in the field, it was a gyoza(dumpling)-making machine he

encountered on his visit to a certain food company that became a turning

point. This gyoza(dumpling)-making machine was a latest model of its

kind, but from the technical standpoint of automotive engineering, it

seemed there was a room for many improvements. Moreover, the work of

squeezing the dumpling skin and cutting it out with the mold was,

essentially, the same as the pressing work done with the mold in

automotive industry.

"I can make it better", Ukei was convinced, and alongside his main business, he diligently continued his research, and finally completed the first machine at the end of 1975. The large-sized automated gyoza making machine named "T-8" was the first of the own brand product that was sold.

"I can make it better", Ukei was convinced, and alongside his main business, he diligently continued his research, and finally completed the first machine at the end of 1975. The large-sized automated gyoza making machine named "T-8" was the first of the own brand product that was sold.

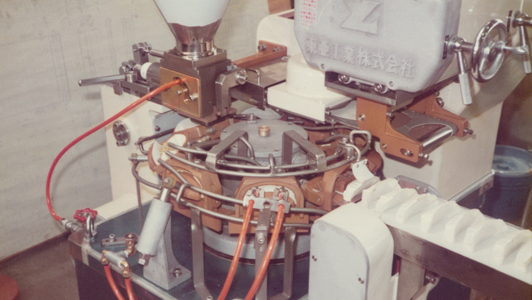

On

December 19, 1975, Toa Industry's first complete machine was released.

With 8 trays, it could produce 4,800 dumplings per hour. Unlike the

existing gyoza(dumpling)-making machines made by other companies, it was

characterized by completely automating the loading of the fillings, and

gained attention with its high production efficiency. The photograph is

a prototype.

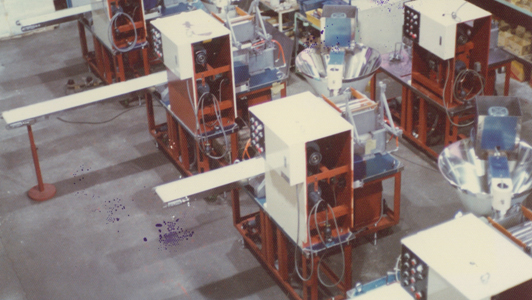

Head

office factory at the time. Many large gyoza(dumpling)-making machines

are lined up tightly. At the time, the main clients were the major food

corporations, and the machine was to make dumplings for supermarket

products and frozen foods. The gyoza dumplings that were previously time

and effort consuming side-dish, became a familiar dish that was easily

purchased and served at dinner by busy housewives.

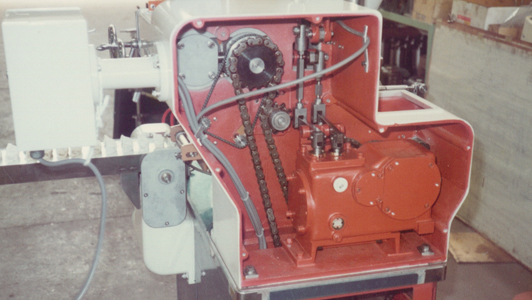

There

were many twists and turns before completing the pallet mechanism which

continues to the present. One such is this photo Here, too much

emphasis was placed on reproducing the hand movement of the person, that

the wrapping mechanism became too complicated, and this model was never

adopted.

This

photo illustrates well that the manufacturing roots of Toa Industry are

in cars and motorcycles. Using the technology proven in automobile

engines and drive systems of motorcycles, Toa products possessed high

durability and reliability right from the initial model.

1980s

Arrival of the compact gyoza(dumpling)-making machine

that would replicate the tastes of restaurants

Approximately 200 units were released to the

world within 5 years of the appearance of the first machine "T-8". By

gathering feedback from customers, next model "T-16" was developed with

various improvements such as the changes in the fillings loading system,

receiving high acclaim even from the well-established traditional

restaurants for replicating the taste and the texture, and became a big

hit. Improvements were continued to be made, and the successor machine

"TX-16-DL" realized high maitainability and more than twice the production

capacity of the initial machine, and continues to be the main machine of

Toa Industry to this day.

On the other hand, the machine whose focus was on the "wrapping technique" of Toa Industry which would replicate various sizes and shapes of dumplings, was the the compact gyoza(dumpling)-making machine series which first appeared in 1988. The gyoza dumpling that requires delicate operation by the human hand at various stages of its production, is different in taste, shape and texture for each restaurant and shop. The compact machine was of a size that was possible to be set up in a small private shops, and yet it would faithfully replicate the taste and texture of the restaurant. It did not take long for this machine to be accepted by restaurants and grocery stores all over Japan, and soon became the main product of our comnpany.

On the other hand, the machine whose focus was on the "wrapping technique" of Toa Industry which would replicate various sizes and shapes of dumplings, was the the compact gyoza(dumpling)-making machine series which first appeared in 1988. The gyoza dumpling that requires delicate operation by the human hand at various stages of its production, is different in taste, shape and texture for each restaurant and shop. The compact machine was of a size that was possible to be set up in a small private shops, and yet it would faithfully replicate the taste and texture of the restaurant. It did not take long for this machine to be accepted by restaurants and grocery stores all over Japan, and soon became the main product of our comnpany.

The

compact gyoza(dumpling)-making machine gained great support from

restaurants that have kept their own taste with few personnel. Many

prototypes were created to replicate the individuality of different

dumplings for each shop while bringing out the merits of automation.

Sales

department in the late 1980s. With the hit of the compact

gyoza(dumpling)-making machine, the sales and service network for

individual shops all over Japan was expanded. In addition to selling

machinery, an affiliated company was set up to provide maintenance and

repair services, thereby improving service quality.

1990~

From gyoza of Japan

to gyoza of the world.

In the 1990s, exports began full-fledged to South

Korea and Taiwan from where inquiries were coming since the late '80s.

The pan fried gyoza dumplings went overseas as one of the "flavours of

Japan" along with the gyoza(dumpling)-making machines of Toa Industry.

Also, there were restaurants that added gyoza dumpling to their menu by

installing our machine, and food manufacturers that began the production

and sales of dumplings as a new business with the implementation of our

machine. As a result, Toa Industry took on the role of supporting such

setting up of new gyoza dumpling business. This is the roots of the

current "Support of Gyoza Restaurant Startups".

With the manufacturing spirit nurtured over the years at its core, Toa Industry will continue the challenge of spreading to the world the appeal of dumplings, which has become a food culture of Japan.

With the manufacturing spirit nurtured over the years at its core, Toa Industry will continue the challenge of spreading to the world the appeal of dumplings, which has become a food culture of Japan.

The

"Min kitchen", a movable stall with a compact gyoza(dumpling)-making

machine attached, to perform demonstrations of the actual production at

supermarkets etc. Although this was only a reference exhibit at a food

event, it led to a new approach not only to manufacture machines but

also to propose new businesses using dumplings.

In

2010, by practicing "business proposals using dumplings" ourselves, we

started the business setup support service full scale. As a one and only

company that can support the creation of a popular restaurant from

scratch, Toa Industry is a pioneer of a new road.