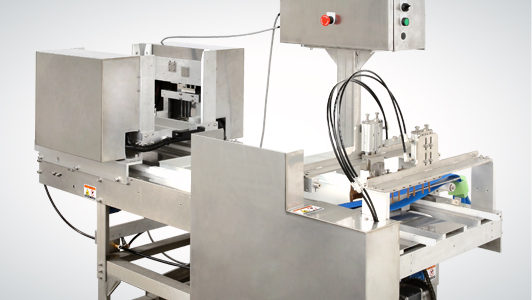

Fully Automated Gyoza Making Machine / Dumpling Machines TX-16-DL TX-16-DL (Compatible with fresh dumplings)

Through improvements made in safety and hygene

we contribute to the value addition of dumplings production.

we contribute to the value addition of dumplings production.

- 10,000 pieces per hour

- HACCP Compatible

- 200V/380V Specifications

To improve on the production, we provide Automated Starch Duster as an optional attachment.

Gyoza Making Machine / Dumpling Machines TX-16-DL

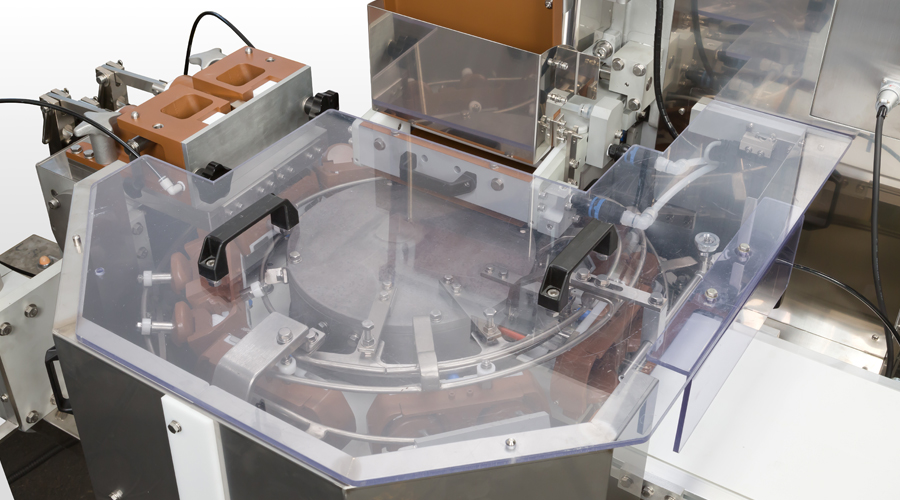

Transparent acrylic cover that is safe and easy to manage hygene control

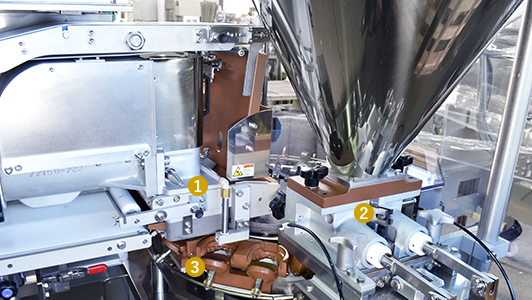

Beltless cutter that prevents the danger of cutoff belt pieces getting mixed in the dough.

Item Information

Item Details

Toa Industry has been pursuing quality and

efficiency of the gyoza machines / dumpling machines for decades. We

have sought improvements in the ease of cleaning, choice of fillings,

safety and hygene control etc. TX-16-DL that is compatible with fresh

dumplings is the next generation machine, a product of years of research

and development that would definitively contribute to the value

addition to the customer's business.

Specifications

| Capacity | 10,000 pieces per hour |

|---|---|

| Molds Qty | 16 |

| Discharge Conveyor | 2 Rows of discharge conveyor |

| Dough Roller Width | 230mm |

| Air Supply | On-site machine to be used. This machine does not come with air supply. |

| Main Machine Measurements | 1280mm×1700mm×1750mm(without optional parts) |

| Electrical Power | 3 Phase 200V/380V 0.40kW |

| Screw Drive | 3 Phase 200V/380V 0.09kW |

| Dough Sheeter Drive | 3 Phase 200V/380V 0.75kW |

| Machine Weight | 1000kg |

Our Videos

Optional Products

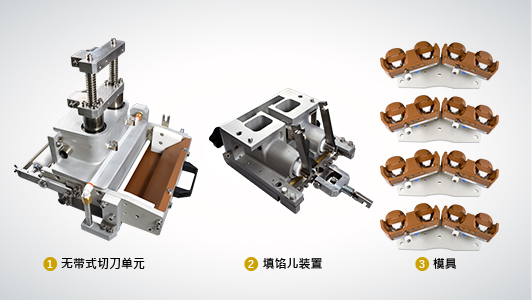

Replacement Units

By replacing the units,

Different sized gyozas can be produced with ease.

By replacing the units made up of a beltless cutter unit, fillings

loader unit and pallet molds, it is possible to produce different sized

dumplings. It supports a wide range of sizes from 15 g to 30 g. As you

become familiar with the replacement work, you can change parts in about

5 minutes, thus contributing greatly to improvement of production

efficiency and sanitation management.The auxiliary machine

You can simply adjust the thickness of the pastry slightly,

Large hand-operated auxiliary noodle machine

In the process of lengthening the texture, if the heavy texture of the dough is directly passed through the dough machine, the texture of the dough will be reduced, and the taste and taste will be different to varying degrees. Not only that, it will also bring great burden to the noodle machine itself, especially in the process of mass production, in the performance of long-term durability, will bring great anxiety to the operation cost. The use of "auxiliary surface machine" is the second stage of the rolling link, on its simple divergent thinking, to reduce the burden of the machine at the same time, and make light and delicious dumpling skin.

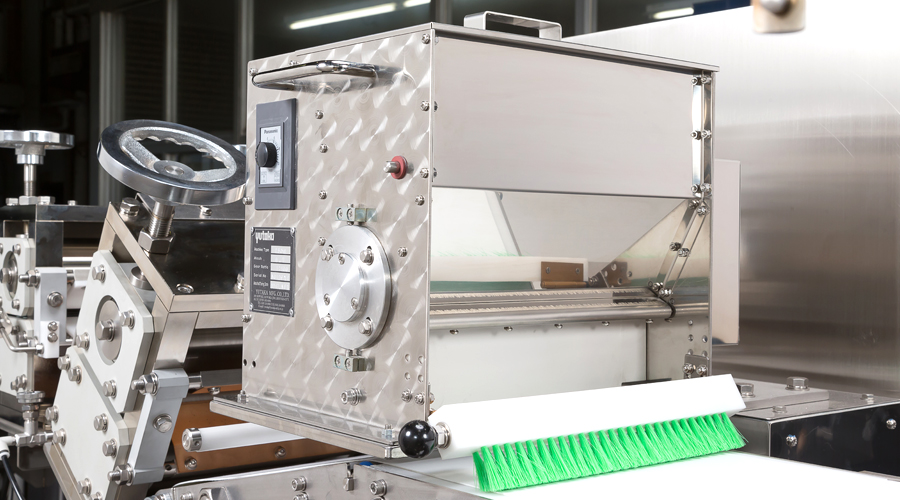

Sub Dough Sheeter

A Sub Dough Sheeter with a large handle

with which the thickness of the dough sheet can be easily adjusted.

During the process of thinning of the dough, if the dough sheet is too

thick when passed through the roller, the dough quality reduces and it

will affect the taste of the dumplings. Additionally, it results in the

overload of the dough sheeter, and is not recommended for mass

production over a long period.By introducing the Sub Dough Sheeter and performing the thinning process in 2 steps, it avoids the above mentioned problems, thus producing fine ideal wrappers for your dumplings.

The next success story is about you.

Introduce to you the customer evaluation of east Asia Industrial dumpling machine.

Go to the example introduction page